Using CAE to support engineering decisions

How we use modern CAE to support engineering workflows

In industrial R&D, engineering decisions are often made before complete data is available. Choices made early in the process have a disproportionate impact on performance, reliability, and downstream validation effort.

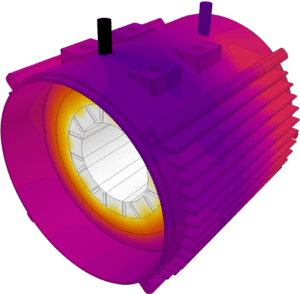

For that reason, we integrate modern CAE tools into our engineering workflows—not to replace testing, but to support better decisions earlier in the design phase.

Today’s CAE platforms are more accessible than they used to be. Improved interfaces, cloud-based solvers, and faster setup allow engineers to evaluate structural, thermal, and fluid behaviour alongside design development. This makes it possible to explore design options, compare concepts, and identify obvious risks before committing to hardware.

Used this way, CAE helps focus physical prototyping on the questions that actually matter. Instead of trial-and-error across many iterations, testing can be targeted and more informative, reducing unnecessary rework later in the process.

By embedding CAE thoughtfully into the workflow, we improve decision-making and predictability in development projects. The value does not come from faster simulations, but from applying engineering judgement to the insights they provide—combined with hands-on testing where it counts.

We use cloud-based CAE tools such as SimScale to support early-stage analysis and iteration.